Editor's Pick

Latest Posts

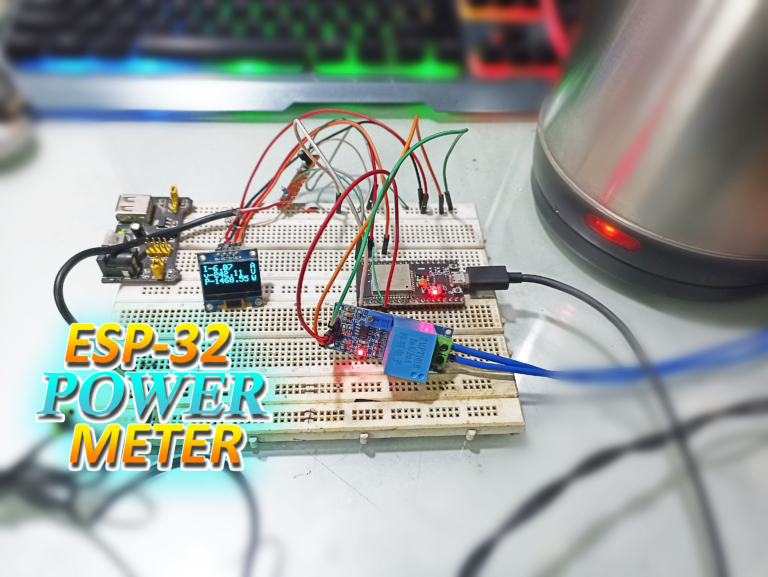

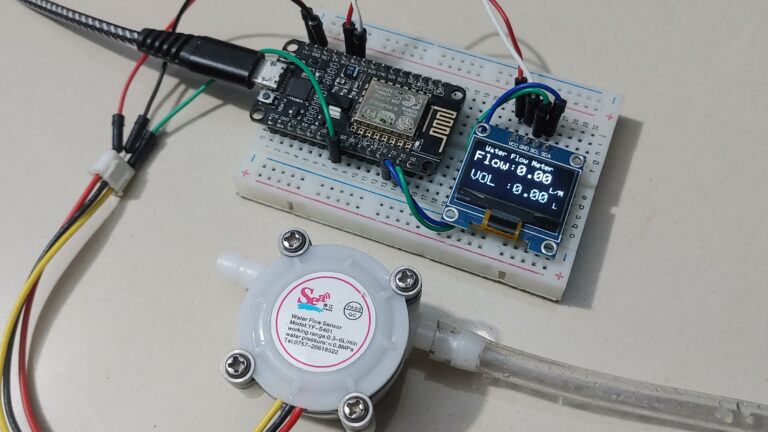

In this project, we’ll build an IoT-based Water Consumption and Flow Meter…

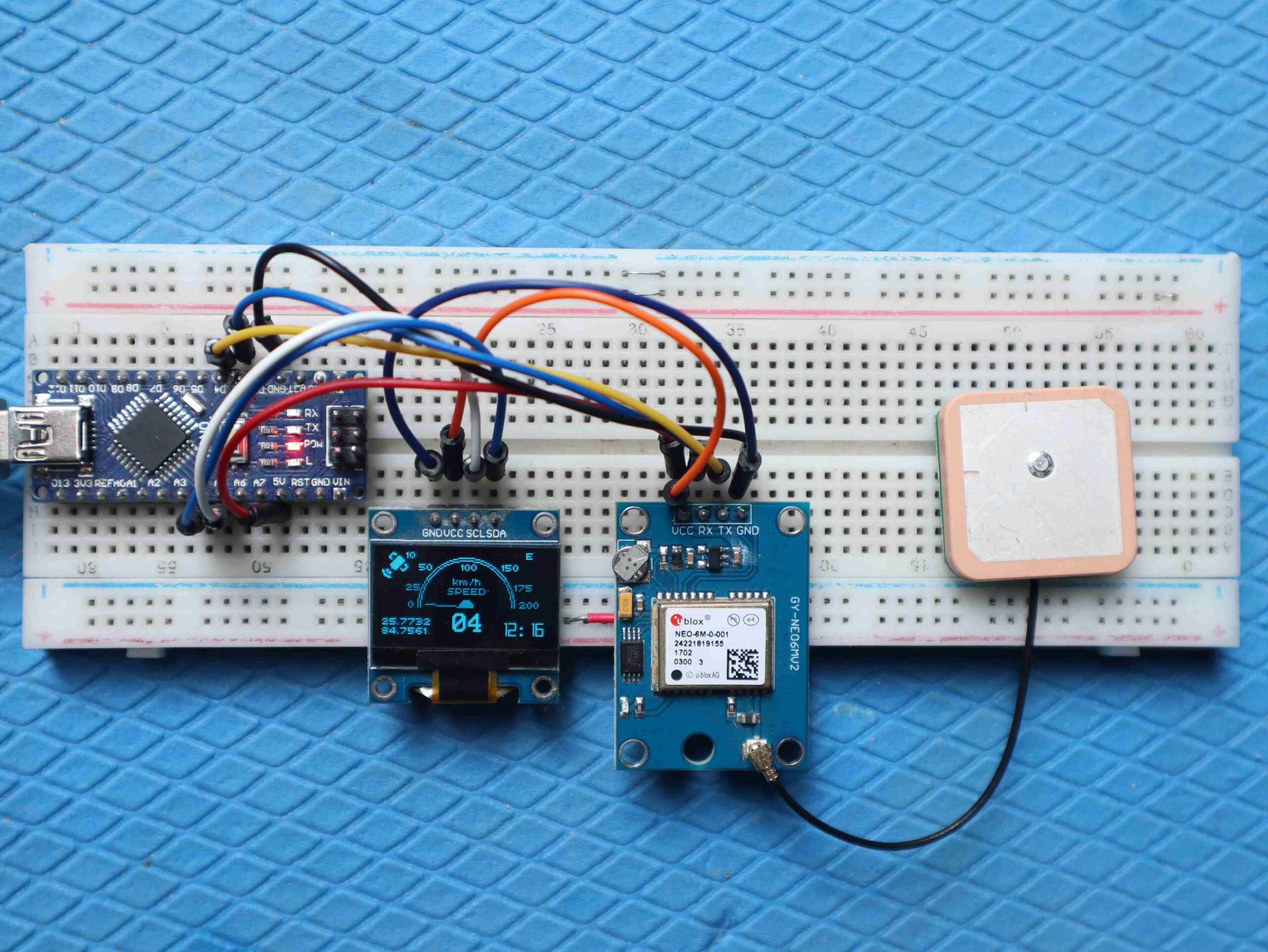

Welcome to this tutorial, where we’ll show you how to build a…

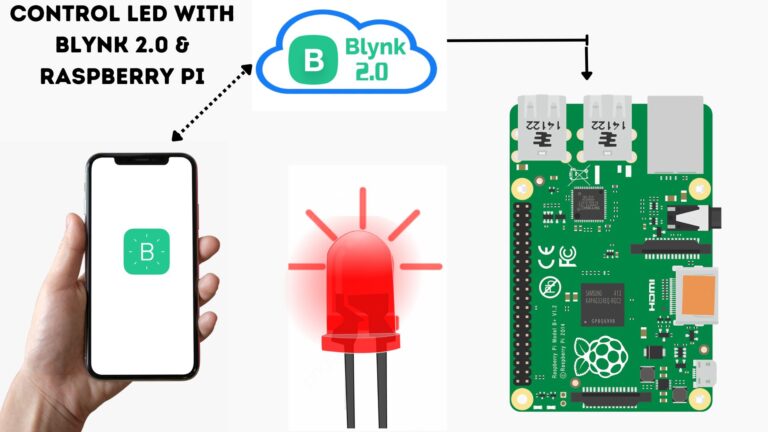

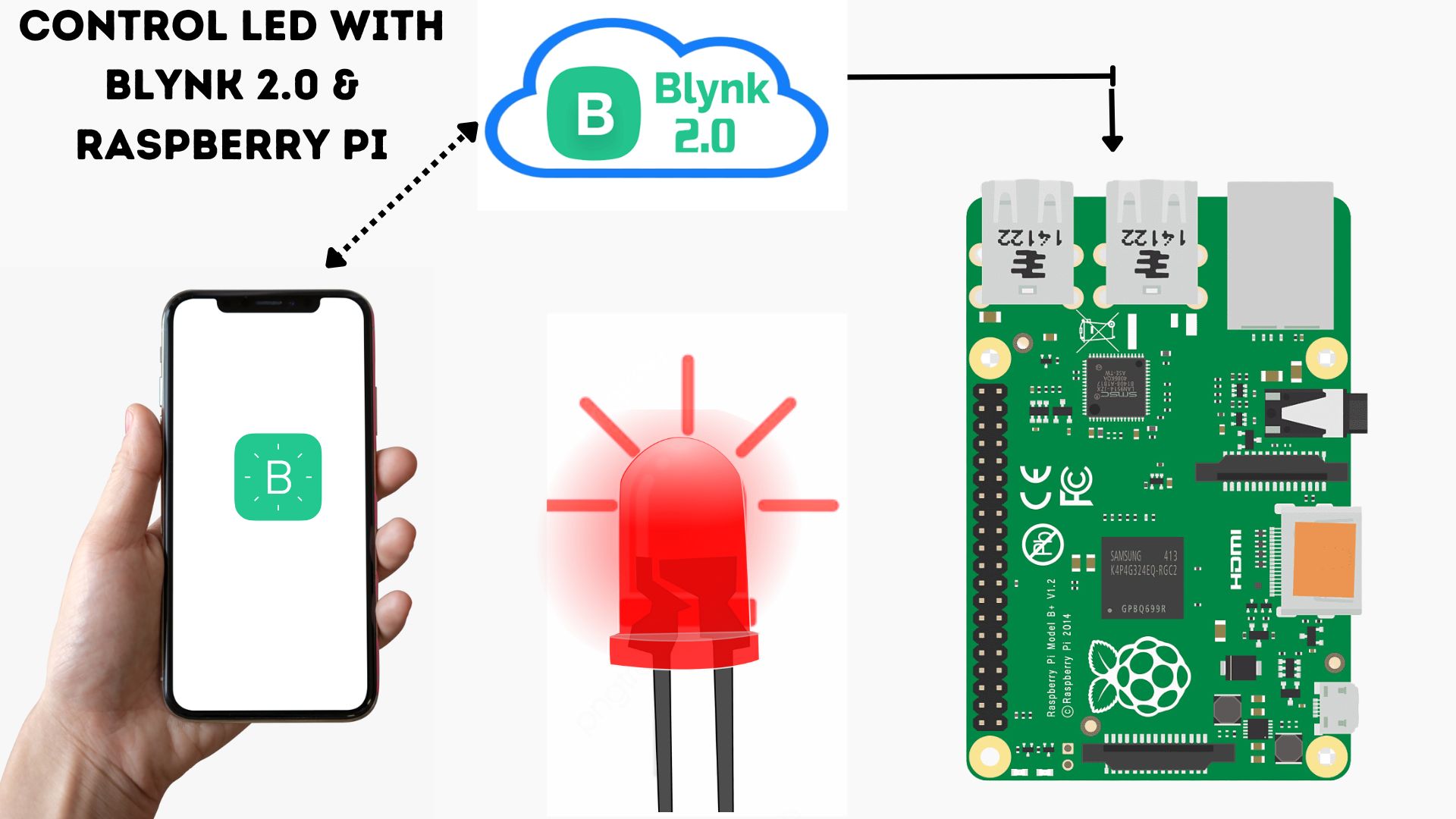

In this tutorial, we will show you how to control an LED…

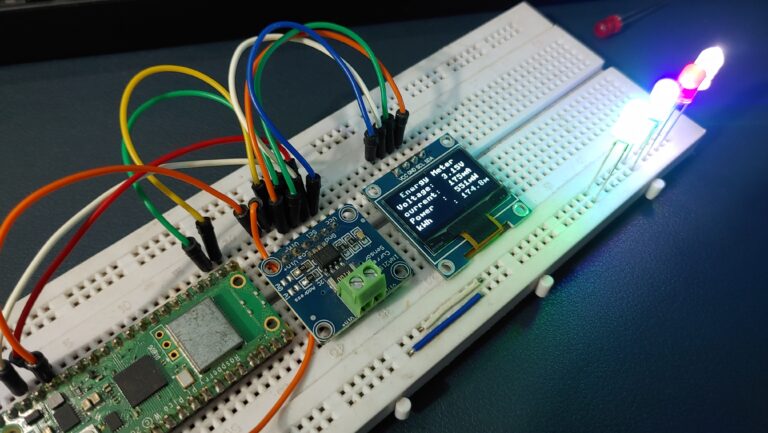

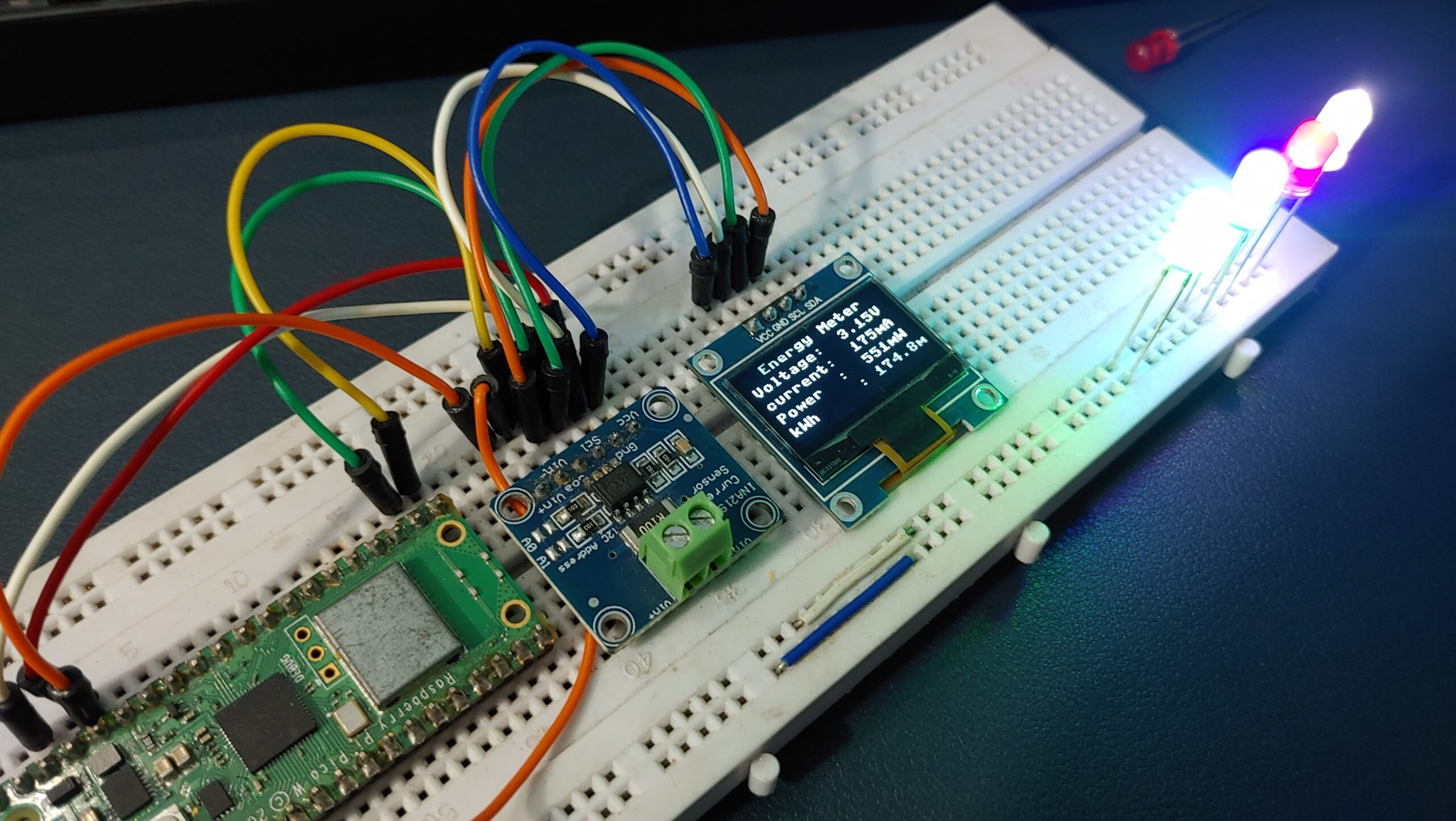

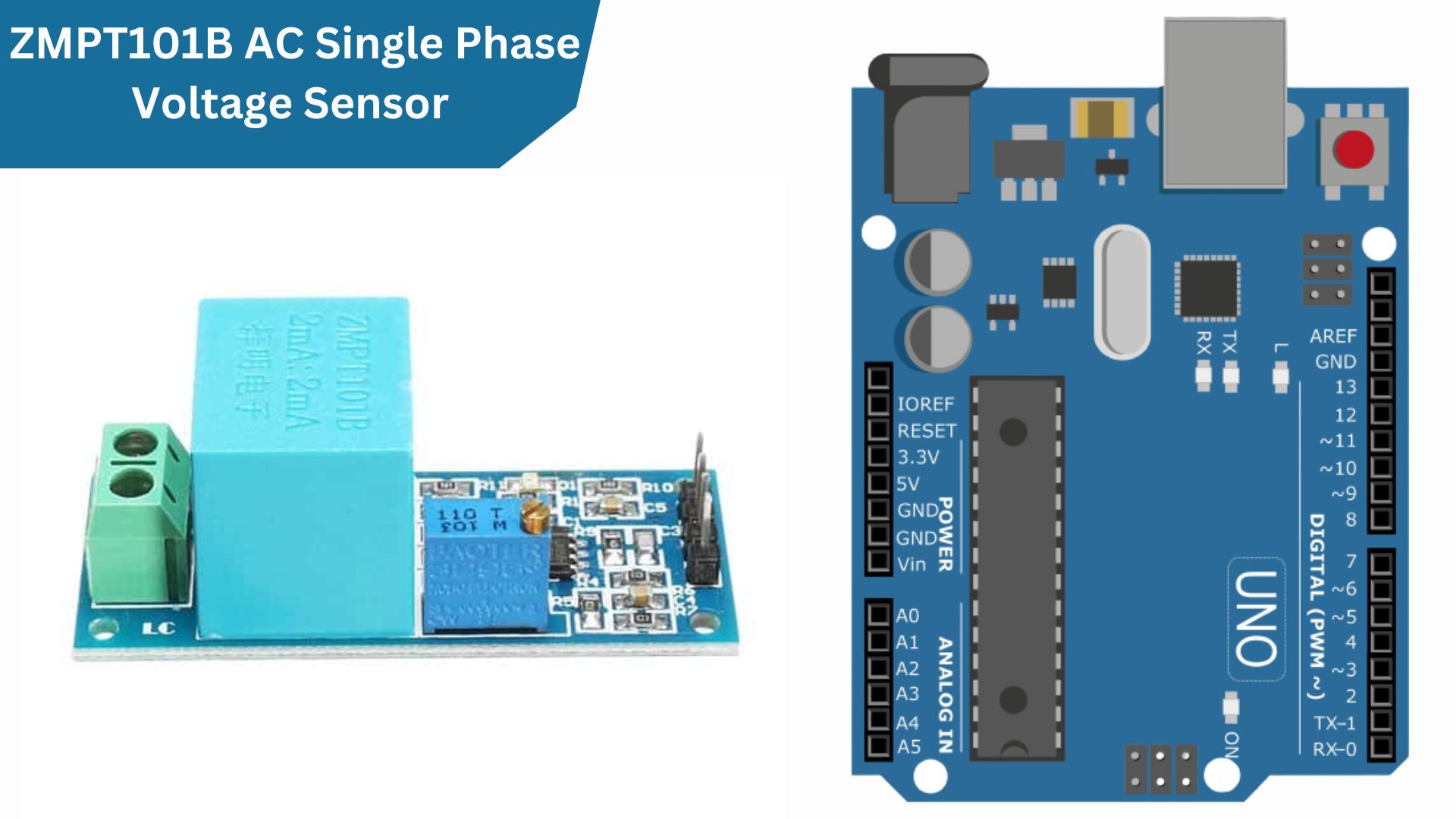

This tutorial shows you how to make a Raspberry Pi Pico-based Power…

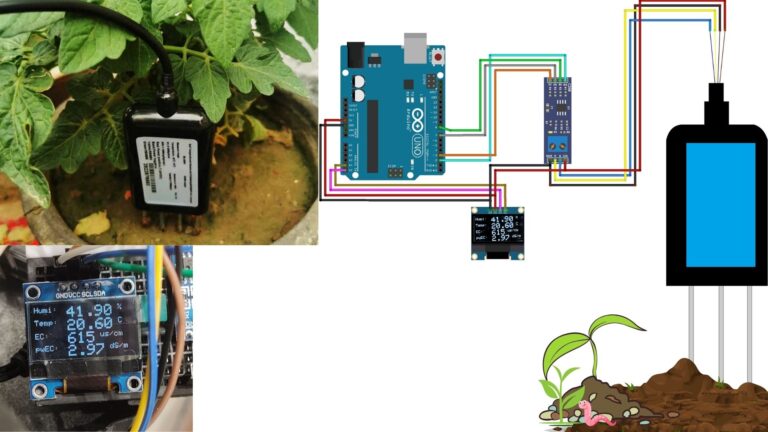

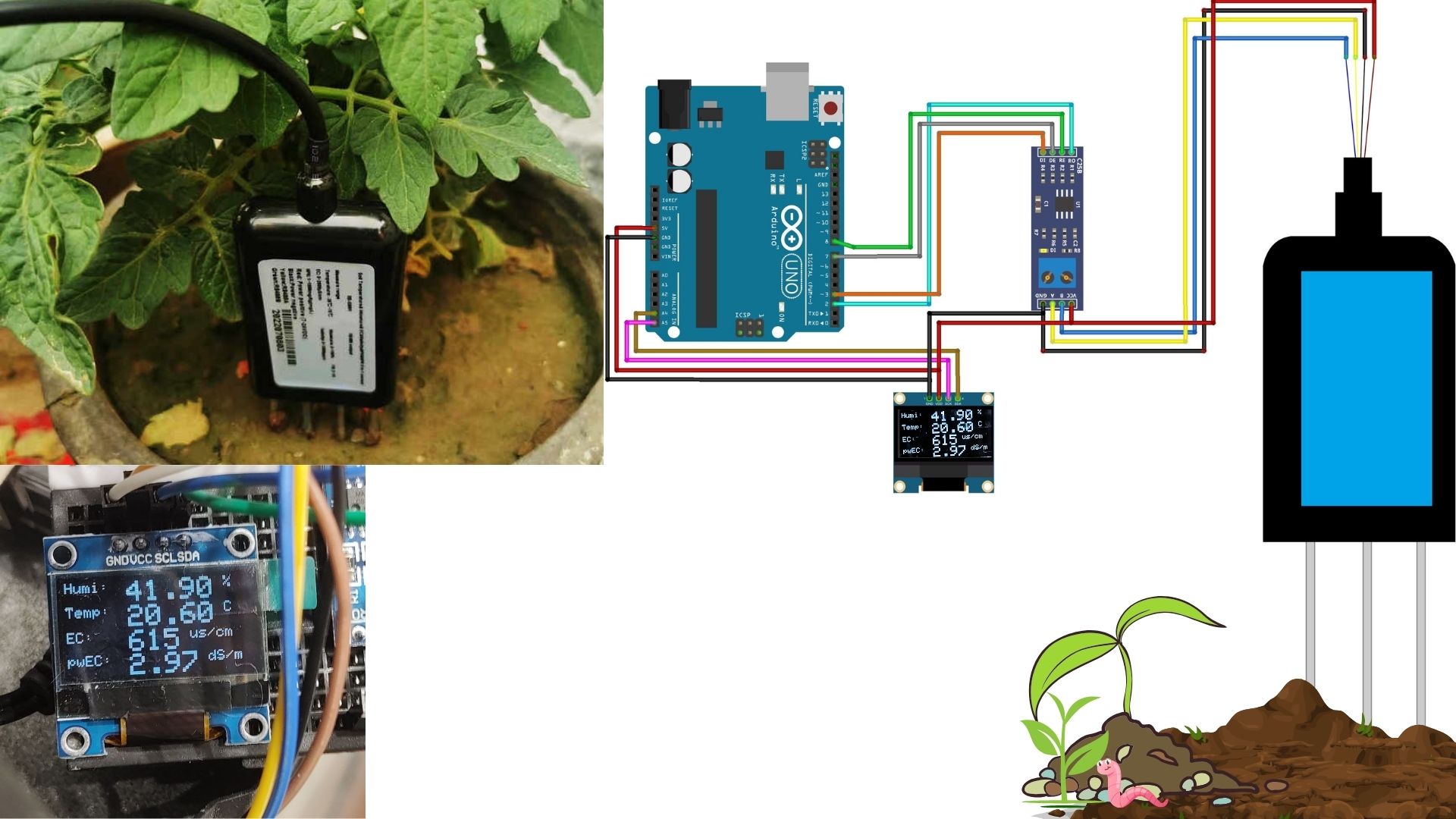

In the past, I have written many posts about Soil Moisture sensors.…

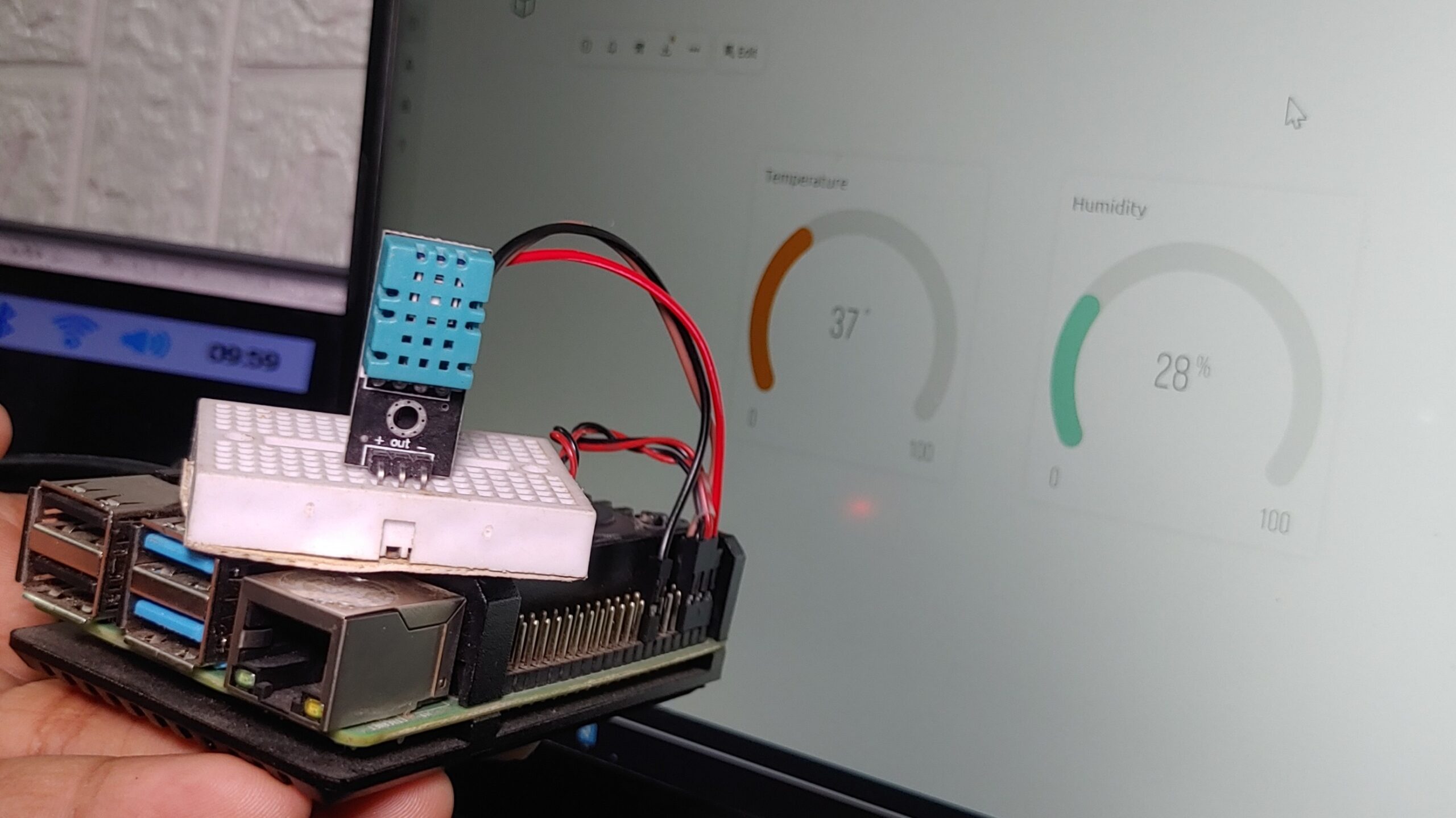

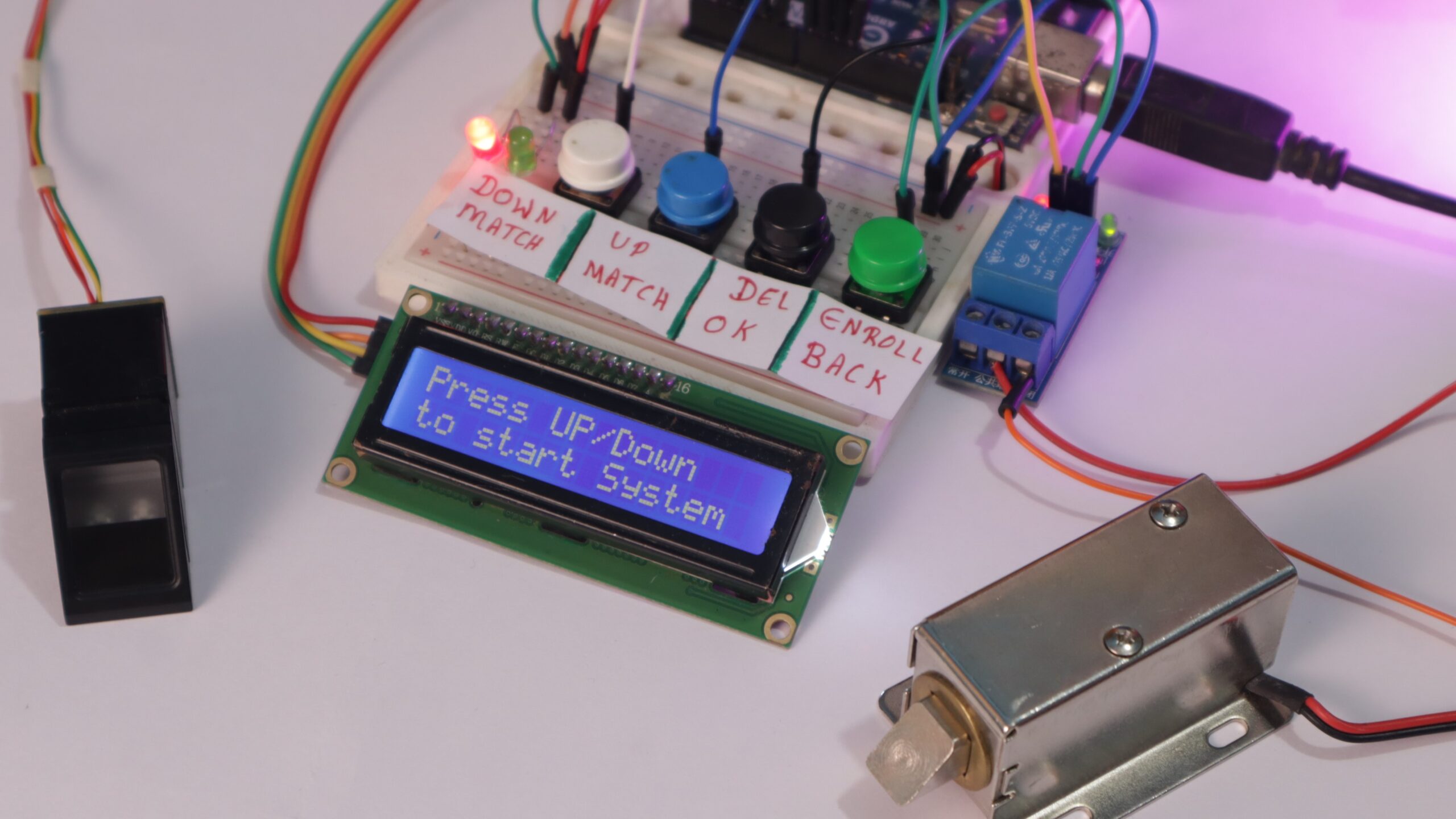

Welcome to this tutorial, where we’ll show you how to build a small IoT Temperature…

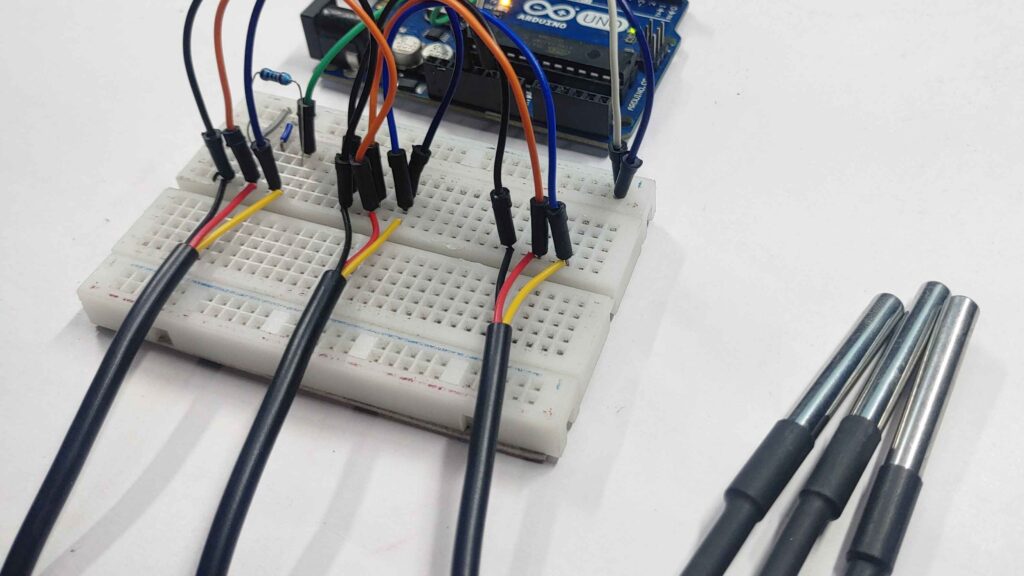

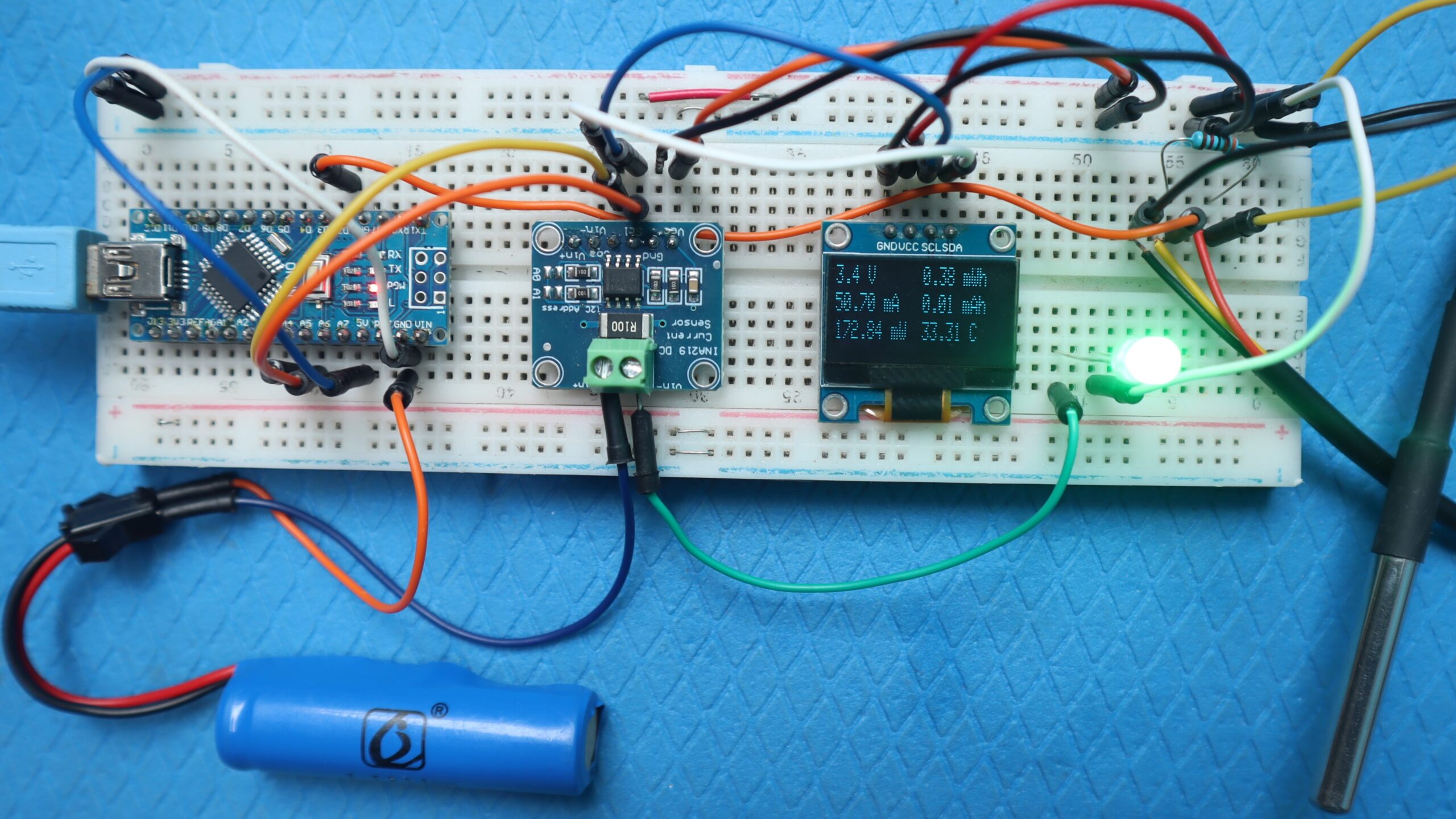

In this tutorial, we’ll interface the temperature sensor, DS18B20 Arduino. The DS18B20 is a digital…

This guide will show you how to get started with your Arduino UNO R4 Minima.…

Categories

- Arduino Projects (77)

- Drones Projects (8)

- ESP32 Projects (12)

- ESP8266 Projects (12)

- IoT Projects (16)

- Micropython Projects (38)

- Raspberry Pi (87)

- Tutorials (38)

Join Our Newsletter Subscribers

About Us

Welcome to ‘DIY Projects Lab’—an online community led by dedicated electronics engineers. Explore informative articles and innovative projects covering Embedded Systems, Power, Analog, Digital, Audio, IoT, AI, Wireless Communication, and Robotics. At ‘DIY Projects Lab,’ we’re committed to making electronics accessible and enjoyable for all. Join our community to share your passion for electronics.